Mobile Stainless Steel Welding: Sanitary Piping and Tanks

When a dairy line pinholes at 2 a.m. or a craft brewery finds a hairline crack in a bright tank weld, there is no time to pull equipment and ship it off for shop work. That is when mobile stainless steel welding earns its keep. Bringing certified TIG skill, clean power, and the right fixtures to your floor keeps sanitary systems within spec and production on schedule. The work lives at the intersection of welding discipline, process hygiene, and practical logistics, and it rewards the team that respects all three.

What “sanitary” really means in welded stainless

Sanitary is not a marketing adjective. In food, beverage, biotech, and pharmaceutical service, sanitary describes a weld and joint geometry that prevents microbial harborage, cleans fully during CIP/SIP, and maintains corrosion resistance over the life of the system. That means full-penetration autogenous or filler-added welds with smooth internal profiles, correctly sized heat tint removal, and no crevices behind clamps or ferrules. The alloy choice matters, of course, but you cannot polish your way out of poor fusion or sugaring.

Standards guide the details. AWS D18 sets acceptance criteria for hygienic tube, ASME BPE drives geometry and surface finish for bioprocess equipment, and 3-A Sanitary Standards define expectations in dairy service. A good mobile welder knows these by heart, or at least knows where the weld will be inspected and to what criteria. You cannot land a consistent ID bead inside 1.5 inch 316L tube if you don’t know the allowable mismatch at a tri-clamp ferrule or how much heat tint is acceptable before passivation.

Why mobile matters for piping and tanks

Some repairs do not tolerate downtime from disassembly. A brewery can lose tens of barrels if a glycol jacket leak forces a tank out of service, and a cheese plant risks a full-day sanitation reset if a pasteurizer weld repair drags into the afternoon. Mobile welding cuts the handling step. With a portable welder, purge equipment, and a clean trailer or truck welding setup, a crew can set up at a loading dock, wheel power inside, and resolve defects on site. It is not cheaper if corners are cut, but it is faster, and it avoids the risks of transport damage and misalignment when reinstalling spools.

Mobile does not mean compromised. A serious on site welding services rig carries filtered power, gas distribution, purging gear, lighting, fixtures, borescopes, and documentation tools. The difference between a good mobile welder and a hobbyist with a generator shows up in weld color, bead consistency, and the microbiology results later. In my experience, the shop-quality results are not about the postal code. They are about process control.

Alloy choices and what they mean at the torch

Most sanitary systems are 304L or 316L. Breweries often run 304L for piping and 316L for tanks in direct contact with wort or brine. Wineries lean heavily on 304L. In biotech and higher-chloride environments, 316L dominates, and duplex or 6Mo appear when chlorides or temperatures climb. The “L” grades keep carbon low for corrosion resistance in the heat-affected zone. Even with L-grade filler, overheating and poor purge burn chromium, and you pay for it with rouging and pitting later.

I ask two questions before setting machine parameters. What is the chloride load in service, and what is the clean-in-place chemistry and temperature? A canning line that sees hot caustic and sanitizer runs wants a lighter, cooler weld profile than a low-temperature yogurt line, and purge quality becomes more unforgiving. For filler metal, ER308L on 304L, ER316L on 316L, and matching duplex wires if specified. When welding dissimilar 304L to 316L, 309L can be appropriate, but only if the specification allows it and the inspector agrees. In sanitary service, I try to match 316L to 316L if the dominant alloy is 316L, rather than create galvanic couples at every joint.

Process discipline: TIG, purge, and heat tint control

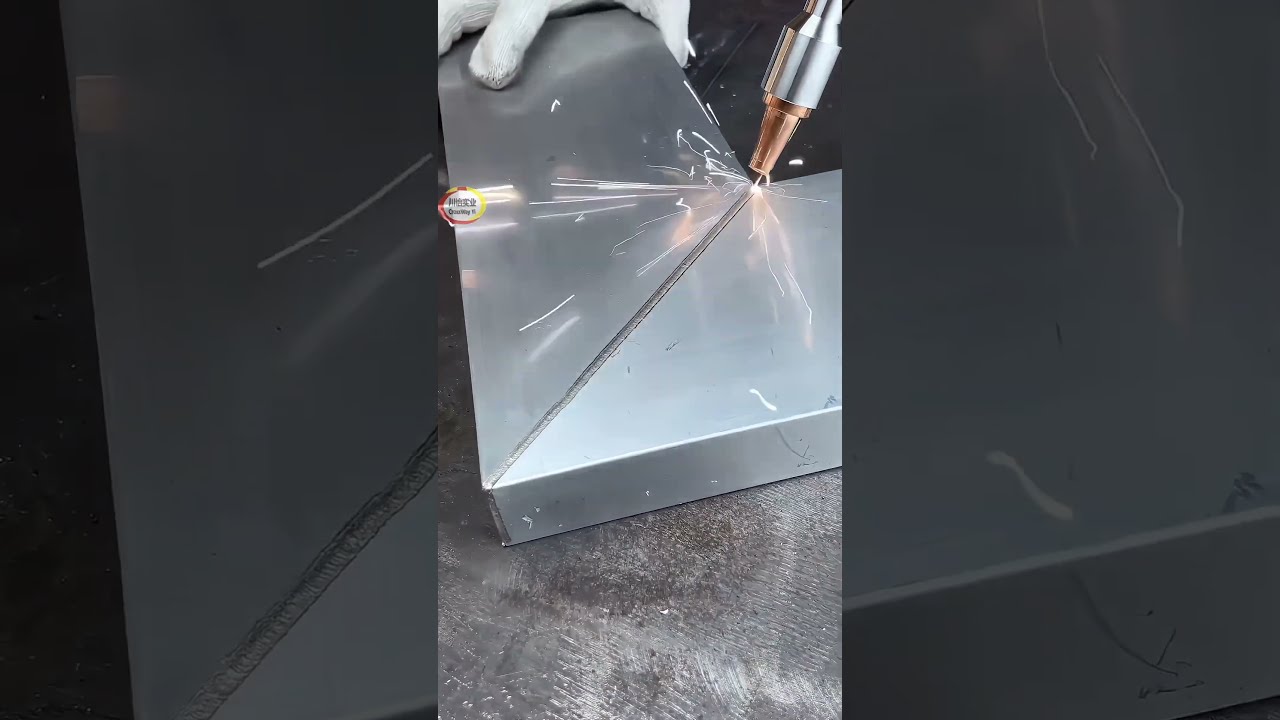

You can MIG sanitary welds with pulsed spray and superb shielding, but for small-bore tube and thin tank shells in hygiene service, TIG remains the standard. The reasons are straightforward. TIG gives control over heat input and puddle shape, you can run autogenous seams for orbital-equivalent quality on small diameters, and it enables perfect tie-ins without spatter. With right settings, a portable welder can produce welds that pass borescope review and slurry corrosion testing.

Purge is non-negotiable. Argon purge on the ID prevents sugaring and oxide thickening. For tube 1 to 3 inches, I use inflatable purge dams or a simple purge plug with a vent hole designed for slow, laminar flow. Flow rates sit low, often 10 to 20 CFH on the ID once the volume is flushed, with 15 to 25 CFH on the torch. I log purge start time and oxygen ppm with an analyzer. Most sanitary specs call for less than 50 ppm O2 before striking the arc, and for critical biopharm jobs we aim under 25 ppm. You can smell the difference when purge goes wrong. The bead turns straw, then blue or gray, and the roughness inside invites trouble.

Heat input is managed with tight arc length and travel speed. I run a sharp 2 percent lanthanated tungsten, diameter 1/16 or 3/32 inch depending on wall thickness, and keep arc length the size of the tungsten diameter or less. Cup sizes range from 8 to 12 with a gas lens for better shielding, especially when reaching around a tank seam near a rib or a jacket nozzle. For thin dairy tube, 0.065 inch wall is common, and 45 to 65 amps is typical on autogenous welds, slightly higher when adding wire. On heavier 10 gauge tank shells, expect 75 to 110 amps, but stop chasing speed at the expense of color. A silver to light-straw bead is the goal. Anything darker than brown gets treated and often rejected.

Preparing the joint in a live plant

Most sanitary piping failures I see began with a fit-up compromise. Mismatch and ovality put one edge ahead of the other, the welder chases the high side, and the root thins to razor edges. That root then corrodes or cracks. Mobile crews need to fix rather than repeat those mistakes. In the field, that means bringing alignment clamps, facing tools, deburring kits, and a willingness to cut an extra inch to get back to round, undamaged material.

Cleanliness is the other half. Wipe with lint-free cloth and reagent-grade alcohol, not a rag from the maintenance bin. Keep grinding dust off the area with poly sheeting. Stainless hates embedded carbon steel particles. I have repaired more than one “mystery pit” that traced back to a wire wheel borrowed from the carbon rack. Tool control matters. Dedicated abrasives for stainless, separate wire brushes, and a habit of bagging and labeling them avoids contamination.

Tank work adds geometry challenges. Internal welds around manways and nozzles are awkward, and it can be tempting to take shortcuts with cup size or torch angle. Poor angle means poor shielding, and you end up back with heat tint. Good lighting, a flexible-neck torch, and patience beat speed. On jacketed tanks, beware of heat travel. A tack that looks harmless can telegraph into glycol circuits and loosen scale.

Portable power, trailers, and site logistics

A mobile welder’s rig is a rolling shop. Mine runs inverter TIG machines with high-frequency start and pulsed capability, a compact MIG for structural brackets and non-sanitary attachments, a generator with clean output, and a bottle rack fitted for argon, tri-mix for aluminum welding, and CO2/argon for MIG on carbon steel when needed. For sanitary piping, the focus is on stable low-end amperage and precise gas control rather than brute force. Heavy equipment and the trailer itself matter because bad power kills arc stability. I use power conditioners if I must tie into site power near a loading dock with variable loads. Forklifts starting on the same circuit will make a weld look like a seismograph.

You learn to pack for contingencies. Emergency welder calls rarely arrive with perfect access and lighting. A thin headlamp, non-sparking tools, intrinsically safe lighting for beverage alcohol spaces, lockout/tagout kit, and a borescope live near the door. If a client asks about AWS qualifications, the binder is on hand. Certified welders should show WPS, PQR, and WQT paperwork relevant to the alloy and position. That confidence builds trust and lets you get to work.

Structural attachments around sanitary gear

Many plants ask for quick repairs or additions during a piping job. A ladder bracket, a rail on a platform, a guard for a valve box. Structural work sits near hygienic systems and often requires carbon steel. That is fine, as long as you keep separation. I keep structural and sanitary operations physically apart even on a small site. Grind carbon steel at the loading dock, weld stainless near the tank, and never let spatter drift onto a clean shell. If a project calls for wrought iron fencing repairs or gates and railings on the same visit, I schedule them before any sanitary work and clean down the trailer afterwards. Cross-contamination is invisible until it isn’t.

Aluminum in a stainless world

Aluminum shows up in breweries and food plants on platforms, catwalks, and equipment housings. Portable TIG with AC and a dedicated aluminum welding setup solves cracked struts and bent handrails without tearing down. Shield stainless from aluminum grinding dust. The oxide from aluminum wheels can embed and stain. I carry separate vacuums, tarps, and PPE, and I do not switch back and forth in the same hour. It sounds fussy until you spend a day removing errant gray smudges from a 10,000 gallon tank.

Inside the weld: profile, penetration, and purge dams

A sanitary weld on pipe is not just a pretty cap. The internal profile matters most. With proper purge and fit-up, an autogenous weld on thin tube will create a slight internal reinforcement, often called a bead. It should be smooth, continuous, and free of keyholes, undercut, or icicles. The moment you add filler, you risk building excess on the ID unless you carefully synchronize feed and travel. When a bore camera cannot pass because of a high internal ridge, you are creating a cleaning nightmare. I have walked away from an otherwise decent job because the borescope showed a drip inside a two inch line that would have trapped product.

Purge dam placement determines whether your argon flows across the weld zone instead of rushing past. I cut vent holes small enough to avoid turbulence, and I position dams at least a pipe diameter or two from the joint so heat does not degrade them. On long runs, I segment purge if needed to save gas and time. Sometimes the best fix is to swap a spool and weld on a bench with an orbital head. Mobile does not mean stubborn. Pick the method that yields the best ID.

Heat tint, passivation, and surface restoration

Heat tint is the visible oxide scale that forms on stainless when chromium is depleted at the surface. Light straw can be acceptable on the OD in some specs, but dark brown, blue, or gray must be removed. Inside the pipe, tint should be minimal to none. After welding, the sequence is mechanical cleaning, then chemical passivation. For small areas, pickling paste based on nitric and hydrofluoric acid blends removes oxide and restores the chromium-rich passive layer. You need training, PPE, and ventilation, especially in enclosed tanks. In plants where HF is banned, citric acid systems can passivate but do not remove heavy scale, so you need to avoid creating it in the first place.

I log weld locations, tint levels, and post-weld treatment. It is tempting to hurry away, but documented passivation pays dividends when an auditor asks why one weld inside a transfer line looks different than its neighbors. If rouge appears later, you have a map for where to start.

Testing and verification: hydro, borescope, and beyond

After a pipe repair, pressure testing is straightforward if the line allows it. Hydrostatic testing at a pressure above operating, usually 1.3 to 1.5 times, isolates leaks. Pneumatic with air or nitrogen is faster but riskier due to stored energy. For sanitary piping, a low-pressure nitrogen hold and soap check is often sufficient on small spools. In tanks, dye penetrant can reveal surface-breaking cracks around nozzles and manways, though the developer residue must be thoroughly removed before returning to service.

The borescope is the unsung hero. A quick look at the ID tells you more about future cleanability than any pressure gauge. I carry scopes with articulating tips because straight ones struggle around elbows. Photolog the welds. When a line gets CIP parameters adjusted six months later and fouling reports come in, you can show that the weld surface was smooth on day one.

Pipe repair under pressure, figuratively and literally

Emergency calls have a rhythm. Someone hears a hiss, sees a bead of product on a seam, or watches a tank drip. The temptation is to clamp and go. In sanitary service, a quick clamp can be an acceptable short-term measure on the OD if it does not trap product on the ID, but long-term it is a patch that leads to corrosion. When I arrive, I triage: Is the line safe to depressurize, can we isolate without contaminating upstream product, and do we have enough straight length to make a proper cut and re-weld? It is common to find a previous repair three inches from the new failure. Both go, replaced with a straight, aligned section that restores geometry.

On pressurized wash lines, stainless can erode at elbows where air meets liquid. The weld might be innocent, and the real fix is a long-radius elbow or a diffuser to reduce cavitation. A mobile welder should be comfortable saying, the weld held, but the design did not. It is better to tell a hard truth once than to sell the same repair twice.

When MIG, flux core, or stick belong on site

While TIG is the tool of choice for sanitary seams, other processes still belong in the truck. MIG with stainless wire can tack fixtures, attach non-process brackets, and repair structural frames near equipment. Flux core and stick handle outdoor structural repair on platforms or support legs where wind would blow TIG shielding away. The trick is firewalling these operations from hygienic zones. Weld spatter near a tank shell invites hours of cleanup and potential finish damage. I have used aluminum foil and simple poly shields with magnets to catch droplets when we had to MIG a support bracket in a tight space. Good housekeeping afterward is not optional.

Documenting work for auditors and insurers

In regulated spaces, paperwork travels with the weld. A brief but complete package usually includes welder certifications (AWS D1.6 for stainless structural, ASME Section IX for pressure work, and AWS D18 for sanitary if applicable), WPS numbers, base and filler metal traceability, purge O2 readings, passivation records, pressure test results, and borescope images. Mobile does not excuse sloppy records. A clean digital packet delivered to QA avoids repeat site visits and keeps lines running.

Lessons from the floor

A few patterns recur when you do this work long enough. The first is that contamination hides in the simple stuff. I once chased recurring pitting in a pasteurizer outlet. The weld looked fine, passivated perfectly, and pressure held. The culprit was a wire brush swapped from the carbon toolbox during night shift. We replaced the section, cleaned with dedicated tools, and the problem vanished.

Another is that fit-up beats amperage. A small misalignment multiplied across a run of elbows becomes an ugly weld on the fifth joint. When the arc fights the geometry, stop and fix the geometry. The time you spend with a facing tool saves twice as much grinding and rework later.

Finally, tell the client what they need to hear about access. If a tank nozzle is unreachable without a safe platform, wait and do it right. I have had to refuse to stick my head into a wet tank with CO2 present more times than I can count. Confined space rules exist for a reason.

Working around equipment and heavy traffic

Plants are busy. Pallet jacks zip by, forklifts tilt loads, and the floor gets hosed down between shifts. A mobile welder setting up near a loading dock or in a bottling hall needs to own the space. Barricades, signs, and a spotter are cheap compared to one dented tank or a ruined weld covered in road grit. When heavy equipment must pass, I pause arcs and cover open joints. Dust is the enemy, and stainless punishes laziness with embedded grit that shows up later as a brown smear after a hot caustic cycle.

Fencing, gates, and the edges of the job

Some facilities ask for fence welding at the perimeter or repairs to gates and railings as add-ons. It is tempting to tie those tasks into the same day to save a trip. If I do, they happen at the start or the end, never between sanitary tasks. Truck welding gear picks up abrasive dust fast, and the last thing I want is that dust settling on an open pipe end. The best mobile crews have two mental toolboxes: the clean one for hygienic stainless steel welding, and the rugged one for structural and repair work outdoors. Keep them separate, and everything gets better.

The human factor: training and certification

Anyone can buy a TIG machine. The difference comes from practice and standards. Certified welders who keep current with AWS codes, understand ASME and 3-A requirements, and can read a P&ID will solve problems others miss. On pipe welding in particular, manipulating the puddle at the bottom of a joint while maintaining ID smoothness is a learned skill. A few hours on a mock-up with purge dams teaches more than a week of theory. When I onboard a new welder, we start with autogenous butt welds on 1.5 inch 16 gauge tube, purge monitored under 30 ppm, and we borescope every joint. If the ID is not smooth, we change one variable at a time until it is.

What good looks like

A good sanitary weld in the field makes itself boring. The bead is consistent, color stays within silver to light straw, tie-ins are invisible, and the ID shows a gentle crown without drips. The purge log shows oxygen below target before arc start and stable during the weld. The joint cleans with a quick passivating treatment, and you do not find flash rust after rinse. On tanks, the HAZ blends, and there is no distortion at manways or nozzles. If you run your finger across the inside, you feel nothing to catch a glove. That is the standard that keeps product safe and maintenance calls rare.

A simple field checklist for sanitary welds

- Verify alloy, wall thickness, fit-up, and ferrule alignment before striking an arc.

- Purge to spec and record O2 ppm, then shield with proper cup and gas lens.

- Control heat input to maintain light straw or better color, inspect the ID with a scope.

- Remove heat tint and passivate per plant policy, document treatment and dwell time.

- Pressure test or leak-check as appropriate, and deliver a clean, labeled record set.

Choosing a mobile partner

If you are evaluating on site welding services for sanitary piping and tanks, ask to see ID photos of past work, not just OD glamour shots. Review certifications and WPS numbers against your process alloys. Ask how they manage purge, passivation, and documentation. Visit the trailer if you can. A tidy rig with dedicated stainless tools, labeled gas bottles, and a logical layout tells you a lot. The right mobile welder brings more than a hood and a machine. They bring judgment that has been paid for in long nights and clean inspections.

Mobile stainless steel welding is equal parts craft and systems thinking. Do the small things right, from purge holes to paper logs, and the big things take care of themselves. The result is simple: sanitary piping and tanks that stay in spec, clean easily, and let your team focus on brewing, bottling, mixing, or fermenting, not on chasing leaks.

On Call Mobile Welding

917 J Pl Suite 2, Plano, TX 75074

(469) 750-3803