Wrought Iron Fence Fabrication and Installation On Site

Wrought iron fence work lives at the intersection of craftsmanship and logistics. The best results come from disciplined prep, sound welding technique, and a jobsite plan that respects weather, uneven terrain, and the realities of power and access. I have fit panels on sloped lawns where a quarter inch decided whether a gate swung true. I have welded pickets in a January wind where preheat made the difference between a clean bead and brittle spatter. What follows is a detailed look at how to execute wrought iron fencing, gates, and railings on site with a professional process that stands up to inspection and time.

Where On-Site Fabrication Makes Sense

Shop-built panels are efficient when lines are straight, access is clear, and tolerances can be controlled under roof. On-site fabrication wins when conditions move, literally. Renovations, compound grades, irregular stone walls, or existing columns that are out of plumb by half an inch will eat a prefabricated panel alive. A mobile welder can collect real measurements at the posts, set fishplates to suit each run, then fit and weld pickets with actual spacing that looks right from the street, not just on paper.

Gates are another strong candidate for field work. Hinge alignment, latch engagement, and ground clearance rarely match a plan once the concrete sets. Setting the frame true to the hinge posts, then welding tabs, drop bars, or strike plates on site, avoids the endless cycle of shimming and re-drilling.

Industrial and commercial sites bring different drivers. Loading dock rails, equipment barriers, and fence tie-ins around heavy equipment often have to work around embedded plates, utility stubs, and bollards. In those environments, on site welding services keep downtime low, and small adjustments, such as adding gussets or changing a picket count, can be made with a welder and a smart tape, not a return trip to the shop.

Material Choices and Their Implications

Traditional wrought iron, the puddled, fibrous material of old gates, is rare today. Most “wrought iron fencing” is fabricated from mild steel, typically A36 or similar. Many installations mix materials: mild steel frames, stainless hardware for corrosion resistance, and aluminum caps or accent pieces when weight or decorative form calls for it. Each choice shifts how you cut, prep, and weld.

Mild steel gives predictable MIG and stick behavior, takes primer and paint well, and offers a good balance of strength and cost. Stainless steel welding on a carbon steel frame is possible for discrete components like hinges or lock housings, but you must control cross-contamination or you will seed rust. Aluminum comes into play for lightweight gates or decorative scrolls, but joining aluminum to steel requires mechanical methods or bimetallic transitions, not direct fusion. If a client asks for a full aluminum fence near salt water, be honest about galvanic separation, proper fasteners, and the realities of TIG versus MIG aluminum welding in the wind.

Pipe and tube are the workhorses. Schedule 40 pipe offers robust posts, especially for industrial sites or high-traffic locations like schools and loading dock perimeters. Square tube frames, 14 gauge to 11 gauge, keep lines clean and make mounting pickets straightforward. For large gates or structural spans, heavier wall thickness and certified structural details, such as full penetration welds and tested hinge pins, move the work into the structural category, where AWS procedure knowledge matters.

Welding Processes in the Field

A portable welder mounted on a truck or trailer gives you options. On a calm, dry day, short-circuit MIG on mild steel is fast and clean, and with proper shielding gas management you can produce quality joints outside. MIG’s downside in the field is wind. Shielding gas does not like a gusty alley between buildings. The workaround is wind screens and smart positioning, or switching to flux-cored wire. Dual-shield flux core can deliver high deposition and excellent mechanical properties, but it demands correct polarity, more cleanup, and proper storage of wire to avoid moisture issues.

Stick welding still earns its keep on fence work. It handles dirty steel better, laughs at wind, and produces stout welds. For pipe welding on posts, 7018 low hydrogen electrodes, kept in a rod oven, produce strong, ductile welds. For root passes on tighter joints or poor fit-up, a 6010 or 6011 can dig through scale and stop-starts, followed by a 7018 cap. When the project requires certified welders, inspectors often prefer stick or dual-shield flux core with documented procedures.

TIG has its place for stainless and aluminum, or when you need a refined, clean bead on visible features like top rails of decorative railings. TIG outdoors is fussy. Wind breaks, clean joints, and dry conditions become mandatory, and productivity falls relative to MIG or stick. Use TIG where the result justifies the time: stainless caps, polished rail ends, or custom hinges that will be seen up close.

Walk the Line: Survey and Layout

Any fence layout starts with control points. I establish a baseline, then verify setbacks, easements, and property lines with the client present. On residential jobs, I set string lines for the run, then mark post centers with paint on the ground, noting transitions at corners, gates, or where a garden bed bites into the line. For long runs, I record grade changes every 8 to 10 feet with a laser level or builder’s level. That data tells you which panels will need racking, stairs versus level segments, and the best places to hide small step ups behind shrubs or columns.

When I meet existing masonry, I map the brick, block, or stone joint layout. Anchors hold best in solid sections, not mortar joints. On stone walls, I sometimes drill and epoxy sleeves for posts to slip into, then grout with non-shrink. That approach avoids point loading and gives a straight plumb post even if the crown of the stone varies by half an inch.

In industrial yards, I look for buried utilities, conduit stubs, and drainage swales. A loader operator might ask you to move the line two feet to clear forklift turn radius near a loading dock. Having a mobile welder and flexible field plan lets you adapt without blowing the schedule.

Posts, Footings, and the Hidden Work

The fence only looks as good as the post layout. For driven posts, a gas or hydraulic driver makes quick work on clay or loam. In rocky soil or frost zones, I switch to concrete footings. Hole size depends on soil and load, but a typical residential post uses a hole 9 to 12 inches in diameter, 30 to 36 inches deep. For gates or high wind exposure, deeper and wider is smart. Bell the base if soil allows. Carry the concrete above grade by an inch to shed water, then slope it away.

I set posts with braces and a light string line. If the run is long, I break it into spans between permanent references, like corners or gate posts, to avoid cumulative error. For core drilling into a slab or header, vac away slurry and use epoxy anchors rated for overhead or sustained tension. Gate hinge posts carry significant moment. For a 6-foot-tall, 4-foot-wide steel gate, wind can put hundreds of pounds on the hinge line. I prefer schedule 40 pipe or 3 by 3 inch tube with a 3/16 wall for most residential gates, larger if the gate carries a motor or decorative panels.

For embedded plates on concrete walls or structural steel, I often weld threaded studs to a backer plate in the shop, then epoxy anchors or set Hilti-style expansion anchors in the field. That approach keeps the fence removable for maintenance but secure against pull-out. When permitted loads are tight, I consult anchor manufacturer charts and select diameter and embedment depth accordingly.

Fitting Frames and Pickets on Site

With posts set and cured, I dry fit frames. Rectangular tube frames, mitered corners and stitch welded joints, keep weight down while preserving stiffness. I prefer to clamp the frame square using a diagonal measurement method, then tack it off in a controlled sequence to avoid pulling. If the frame is a gate, I add a slight bias high at the latch side, maybe 1/16 inch, because hinges settle with use. The bias keeps the hinge line honest over time.

Pickets come next. Center spacing should match the visual rhythm of the site. A common residential pattern is 4 inches on center for 5/8 inch or 3/4 inch pickets, leaving under 4 inches clear gap to meet many codes for railings and safety. For a higher-end look, I vary spacing to land full pickets symmetrically at the ends, rather than leaving a skinny piece. When stairs or slopes require racking, I set the picket angle to follow grade, then notch the top rail when necessary so caps sit clean. Welding the pickets in a walking sequence, alternating sides, keeps heat balanced.

For decorative elements, collars, rings, and scrolls go on after the structural welds, so you do not trap water pockets or make cleanup impossible. I grind only where it improves appearance or removes hazards. A slightly convex bead that is uniform often looks better than a ground flat that reveals undercut or ripples, especially with a satin paint.

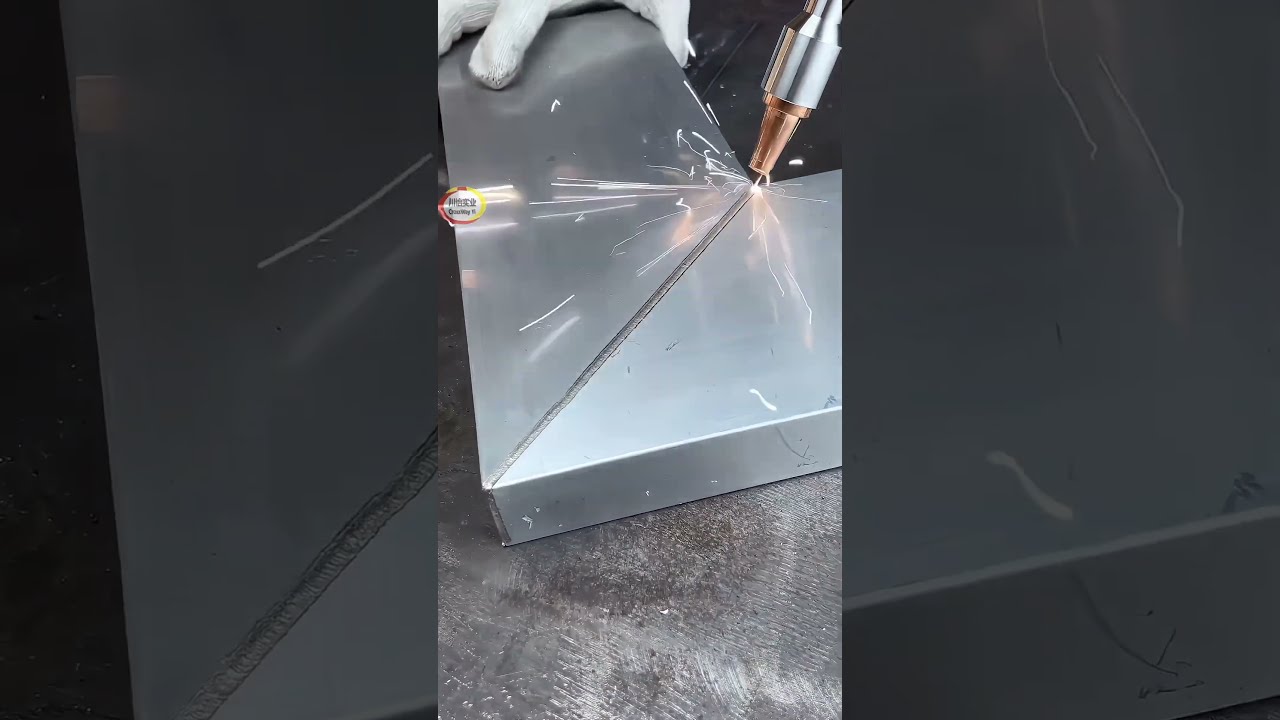

Welding Parameters, Technique, and Quality Checks

A mobile welder setup should carry enough amperage to run 1/8 inch 7018 with confidence, and a MIG with at least 200 amps for heavier joints. For fence work, many joints sit in the 14 gauge to 3/16 range, which is in the comfort zone of 0.030 or 0.035 solid wire with C25 gas. If wind picks up, flux-core 0.035 E71T-11 for self-shielded work, or E71T-1 dual-shield with gas if the site allows wind screens, can keep you productive. Always test a sample joint on scrap of the same thickness and condition. Slight adjustments in voltage and wire feed make a visible difference on exposed picket joints.

For stainless steel welding, I protect the puddle and the backside with argon when necessary, and I keep dedicated brushes and grinding wheels for stainless. Cross-contamination shows up months later as ugly rust spots. Aluminum welding on site calls for a spool gun or a well-tuned push-pull system and a tight joint fit. Wind is a real enemy for aluminum TIG and MIG. Set wind breaks, schedule those welds for early morning when air is calm, or move the work under a canopy.

Quality checks are simple and direct. I look for consistent penetration at test coupons, no visible undercut, and smooth, uniform beads where they are seen. I check gates for sag by loading the free end and watching hinge performance. A well-set hinge post, true hinges, and a small pre-camber in the gate frame keep everything swinging freely. For long runs, I sight down the top rail from each direction, looking for dips. Small corrections happen with fit up before final welds, not with a grinder afterward.

Coatings and Corrosion Control

Field-fabricated steel will only last as long as its coating. In dry climates, a quality zinc-rich primer and two coats of alkyd or acrylic enamel perform well with periodic maintenance. In coastal or industrial environments, galvanizing is the gold standard. Hot-dip galvanizing after fabrication gives unmatched corrosion resistance, but it complicates field welding. When on-site welding services are required for galvanized steel, I grind the zinc away from the weld zone, weld clean, then coat with a zinc-rich cold galvanizing compound and finish paint. Proper ventilation is essential when working around zinc, and a respirator rated for welding fumes belongs on your face, not in the truck.

For stainless components, I passivate after fabrication. Simple citric acid gels can dissolve free iron and restore the protective layer. If budget points to paint alone, I seal all end cuts and weeps, caulk gaps where water could sit, and design the fence to drain. A top cap on a hollow rail matters. Without it, rain will collect and push rust from the inside out.

Gates, Hardware, and the Details People Touch

Hinges, latches, and stops make or break the daily experience. Ball-bearing hinges handle heavy gates and swing smooth for years. For medium weight, barrel hinges with grease fittings are fine, but weld them well and align precisely. A gate that binds on the final inch will be yanked by the latch until something gives.

Latch choices range from gravity latches to keyed mortise locks. If security is a concern, I fabricate a latch shield to deter bolt cutters and reach-through. For pool gates or code-sensitive installations, self-closing hinges and latch heights matter. I test twice with the homeowner or facility manager watching. A few extra minutes adjusting tension beats a 2 a.m. phone call because the dog escaped.

I add doorstops or ground stops for wide gates to prevent over-travel into a wall or a parked trailer. On industrial sites, I sometimes weld in a receiver plate at the pavement that a drop bolt can seat into. It keeps a 10-foot leaf from drifting in the wind and slamming into forklift paths. For automated gates, I coordinate with the operator installer so that hinge geometry and frame stiffness match motor torque and travel.

Safety in the Field

Every site has its own hazards. Welding near landscaping carries fire risk. I soak dry beds, keep a fire watch for 30 minutes after hot work, and carry a 10-pound ABC extinguisher plus a water can. On public sidewalks, I set cones and keep grinders behind screens. For overhead work, a lift beats a ladder most days, especially when running top rails near a loading dock edge. When pipe welding under a structure or near fuel, I do a formal hot work permit and monitor gas readings if necessary. Personal protective equipment is standard: hood, gloves, sleeves, and hearing protection. A quick conversation with the client about schedules and traffic avoids surprises when a truck needs the lane you just taped off.

Mobile Equipment and Power Strategy

A truck welding rig with a generator drive unit delivers consistent power. I size the machine to handle stick and MIG, plus grinders and a small chop saw. For aluminum, I add a spool gun. Cords and welding leads stay coiled and off the ground where vehicles pass. If site power is available and reliable, I use it sparingly for lights and drills, and keep my machine as the primary welding source. Power fluctuations from construction temp poles can wreck a nice MIG bead.

Carrying the right equipment matters as much as the welder. I stock a selection of clamps, magnetic squares, layout tools, and a light chain hoist for lifting gate frames. A compact band saw or cold saw makes cleaner cuts than a torch or abrasive wheel, and less cleanup means better welds. For pipe repair or fence welding on older runs, a pipe notcher and wraparound templates help make saddles that fit with minimal gaps. That fit translates to stronger welds and less heat distortion.

Certified Work and When It Matters

Most residential wrought iron fencing does not require AWS certification. That changes when the fence ties into structural elements, carries loads beyond its own weight, or stands in environments governed by strict standards, such as hospitals, schools, or public facilities. A certified welder, with procedures documented and WPS on hand, gives confidence to inspectors and clients. If you step into stainless steel welding for food service areas, aluminum welding on platforms, or pipe welding for handrails in a stadium, certification proves you can follow code, not just make a pretty bead.

Even when not required, I follow AWS best practices. Preheat thicker pieces, control interpass temperature, and avoid shortcuts. If a gate frame cracks at a weld because it was tacked with chilly steel against a winter wind, the client does not care that code did not require a preheat. They want a repair, fast. An emergency welder can band-aid a broken hinge, but building it right from the start is cheaper for everyone.

Field Repairs and Maintenance

Fences live outdoors. Trucks bump them, sprinklers bathe them, and freeze-thaw cycles flex them. A clean field repair starts with diagnosis. If a section leans, check the footing, not just the pickets. A cracked or heaved footing needs replacement, not a welded brace that hides the real issue. For bent pickets, I heat gently and straighten with a bar, then assess whether metal fatigue invites a future failure. On cracked welds, I gouge to sound metal with a die grinder or carbon arc if room allows, then reweld with appropriate rod or wire. For pipe repair on posts, a sleeve cut from matching pipe and fish-mouthed to fit can restore strength without an ugly patch.

I leave clients with a maintenance schedule that fits their environment. Painted steel wants a wash twice a year and touch-up on chips before rust spreads. Stainless wants a wipe down and occasional passivation where salt air or road spray can attack. Gates want hinges greased at least annually. Simple habits save expensive replacements.

Pricing, Scheduling, and Setting Expectations

On-site fabrication has more variables than shop work. I quote with contingencies for weather, unforeseen subsurface conditions, and design tweaks that field conditions often demand. I explain the schedule in phases: layout, posts and footings, cure time, frame fit and weld, coatings, hardware, and final adjustments. For a typical residential project of 80 linear feet with one gate, a realistic timeline is two to three weeks from ground break to final paint, depending on cure times and weather. Rushing paint onto green concrete or onto dew-soaked steel is asking for failure.

Clients sometimes ask why a mobile welder costs more per hour than a shop rate. The answer sits in the value delivered on site: the ability to adapt a hinge while the concrete is fresh, to notch a rail around a stone that was not on the plan, to solve a misaligned post with a fishplate rather than a return visit. That agility saves rework and produces cleaner lines that match the actual space.

Common Pitfalls and How to Avoid Them

Poor drainage kills fences. Design weeps, seal tops, and avoid flat horizontal surfaces where water lingers. Over-welding thin material warps frames. Stagger welds, fixture properly, and let metal cool. Rushing coatings leads to peeling. Respect cure times, dew points, and recoat windows. Finally, ignoring the gate is a mistake. Gates get the most use and attract the most complaints. Invest the attention there: better hinges, a true frame, and a latch that your client can operate with gloves or groceries in hand.

A Practical Field Checklist for Install Day

- Verify property lines, setbacks, and utility locations with the client present.

- Confirm material on site: posts, rails, pickets, hardware, primers, and finish coats.

- Set wind screens and fire watch, organize power and safe cord routing.

- Dry fit frames, check square and level, confirm gate swing and clearances.

- Weld in controlled sequence, inspect beads, then clean, prime, and finish to spec.

When Aluminum and Stainless Join the Party

Not every fence is carbon steel. Aluminum shines for wide gates on soft ground where weight matters, or near coastal air where corrosion is relentless. Aluminum requires different joint prep, a clean joint, and attention to heat input to avoid collapse on thin sections. I prefer 6061-T6 for frames and 5052 for sheet infill, with TIG or MIG using 4043 or 5356 filler depending on the application. Mechanical connections to steel posts, with nylon or neoprene isolators, avoid galvanic corrosion. Stainless, particularly 304 or 316, works for railings and high-touch areas. In marine environments, 316 earns its cost. TIG gives the nicest finishes, but dual-shield stainless wire can be practical for hidden joints. Again, keep stainless tools separate. A single contaminated flap disk can ruin a polished run.

Industrial Considerations: Loading Docks and Equipment Areas

Industrial fencing must survive forklifts, pallet corners, and snowplow blades. I design those runs with heavier posts, often 4 inch schedule 40 pipe, and weld baseplates with full-perimeter fillets. I oversize anchors and add backup plates under the concrete where possible. Top rails sit higher to deter climb, and mesh or expanded metal infill can add security. Where gates cross truck paths, I design the hinge line to be shielded, and I add stops to prevent a swinging leaf from striking a trailer. Pipe welding for bollards, tie-ins to guardrails, and brace brackets happens weekly in these environments. The same rules apply: fit tight, weld hot enough for fusion, and protect with industrial coatings or galvanizing.

When Things Go Sideways

Field work teaches humility. I have broken a tap in a stainless hinge plate at 4 p.m. on a Friday. The fix was patience, a carbide burr, and a sleeve insert. I have had a sudden gust turn a perfect MIG bead into porous junk. The adjustment was swift: switch to stick, regrind, and run a clean pass. Clients respect a welder who explains the issue, adapts, and keeps quality first.

Final Thoughts From the Road

A wrought iron fence is a promise of boundary and style. On-site fabrication and installation keep that promise when conditions are less than perfect. Bring the right equipment, choose welding processes that match wind and material, and think like water when designing for longevity. Whether you are hanging a delicate garden gate or welding a run around a loading dock, the fundamentals remain the same: careful layout, solid fit up, clean welds, and honest coatings. The rest is seasoning and pride in work that will still look straight in ten years.

If you need help with fence welding, pipe repair on an old run, or an emergency welder to get a gate back in service, a mobile welder with a well-outfitted truck can deliver solutions in a single visit. Good fences start with good planning, and they last with good welding.

On Call Mobile Welding

917 J Pl Suite 2, Plano, TX 75074

(469) 750-3803